PEAK

What—

A packaging design concept based on an airtight coffee canister design. Within this project I explored packaging design, branding, and graphics.

Why—

A large focus of this project was on manufacturing techniques and the idea of creating a identity in both graphics and form.

Product Statement—

For this project, I developed a company identity and brand, peak, and created my designs keeping in mind the following mission statement and base product description:

PEAK aims to redesign traditional packaging and develop innovative storage solutions rooted in simplicity and functionality. The 001 reusable canister comes packed with PEAK brand coffee in a variety of roasts and blends, combining premium fair trade ingredients with high quality, sustainable packaging.

Research—

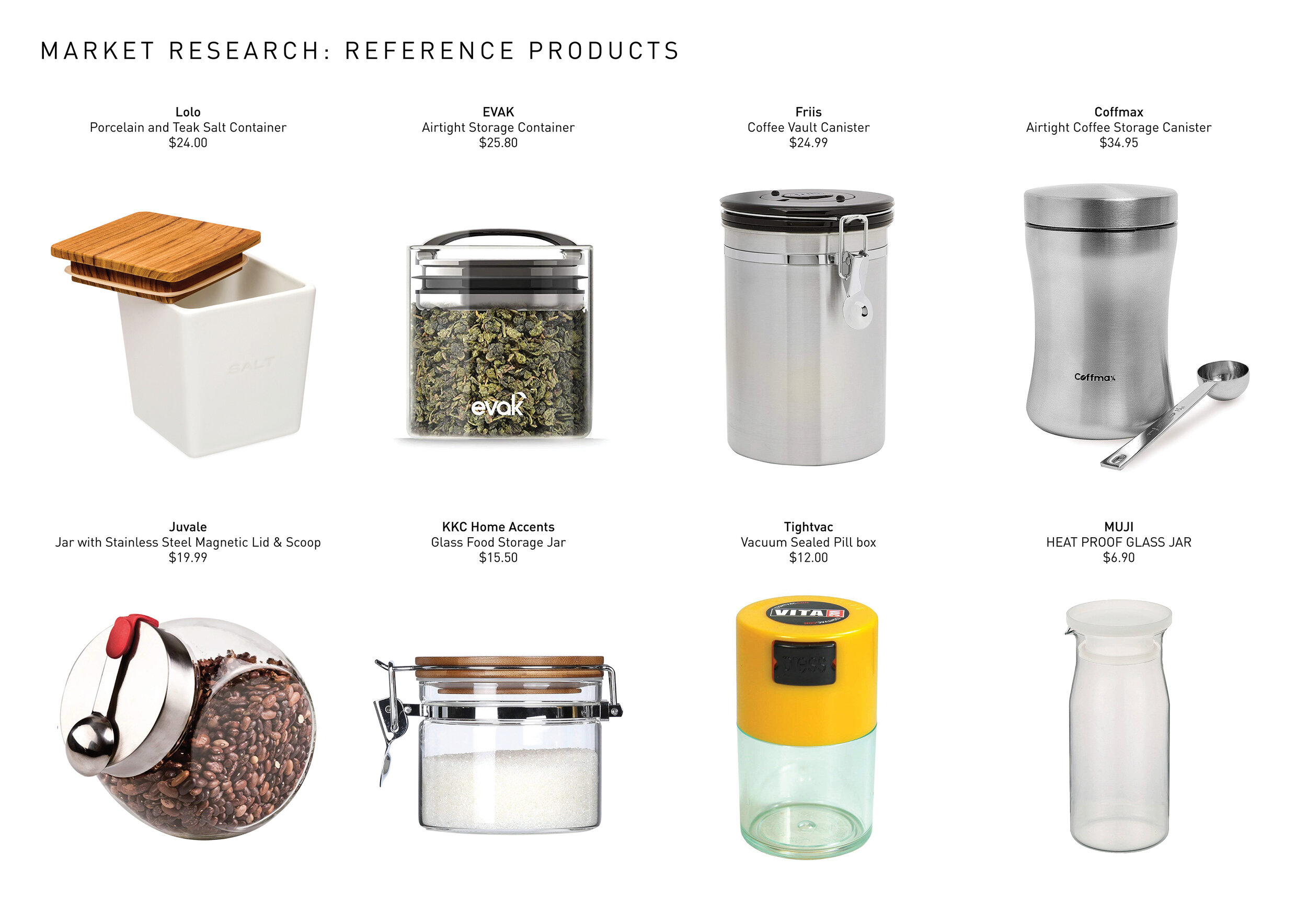

I went on to begin design research, producing general function trend boards, problem analyses, a mood board, and focussed product research.

(click to enlarge)

Window Feature and Scoop —

After exploring various options I chose to head in the “PEAK” window direction in regards to product design and branding. The PEAK window feature is set into the canister lid, reducing general air and light exposure to the contents of the can while allowing the user to see the amount of coffee grounds or other ingredients remaining in the can.

The canister comes equipped with a heaping tablespoon scoop. The scoop is secured with a magnetic connection between the handle and the indented canister lid. in order to release the scoop simply lift the extended end of the handle.

Pictured to the right is the V1 lid indentation where the magnetic scoop would rest and set in PEAK window. Below is the scoop presented above the canister.

Branding—

The PEAK logo is based off of the canister window features that span across product lines. The word peak paired with the eyeball imagery signals to the glancing action, while the brand name also denotes the superior performance and quality of the product. The lettering is rounded to suggest a friendly, modern tone.

Printing Specs—

The paper sleeve will be cut to size (likely with an industrial laser cutter) with the respective attachment notches. All text and imagery on the paper sleeve will be printed using flexography in the CMYK colorspace. A dark blue barcode with the light cream background will be used to maximize function. The medium roast sticker color will be printed in the displayed Pantone red shade, while dark roast and light roast will be printed in correlating lighter and darker shades.

The “PEAK” logo will be printed separately with a pure white on the stainless steel metal shell of the reusable container using serigraphy.

General Features—

The 001 canister is sold both individually as well as packed with PEAK brand coffee beans. The 001 canister with coffee is securely sealed and wrapped with a cardboard sleeve. Printed on the sleeve are the canister features, branding, general info, and coffee plant graphics. A sticker containing the content information is placed in a designated rectangle during manufacturing and packaging. The sticker states the roast, region of origin, general taste profile, and ingredient details.

Manufacturing Details—

The PEAK 001 canister with coffee consists of the stainless steel metal container with plastic lining, a magnetic scoop, an airtight lid with a clasp closure and a PEAK window, and the thin cardboard branding sleeve secured around the canister. The reusable 001 canister shell will be made with stainless steel using a three-piece can method with the walls rolled from a cylinder and the seams joined with welding. Inside the steel shell, a plastic interior lining made of Polyethylene terephthalate will be fit. Airtight technology using a flexible rim ring and hermetic clasp will be used. The lid closure will be made with a similar process and fit with the clasp. The scoop will be made in two pieces (handle and head) and welded together.